| Сайт бесплатных объявлений |

Личный кабинет

|

Конструкторское бюро “ПАРУС” является одним из ведущих производителей: фасовочного, упаковочного оборудования

г.Киев, ул. Краснозаводская, дом 7, 04101 Kiev

☏ +38 (044) 209-64-04 ✉ andrei@kbparus.com.ua kbparus.com.ua

☏ +38 (044) 209-64-04 ✉ andrei@kbparus.com.ua kbparus.com.ua

Австрия | Товары | Оборудование, Инструменты | Предложение

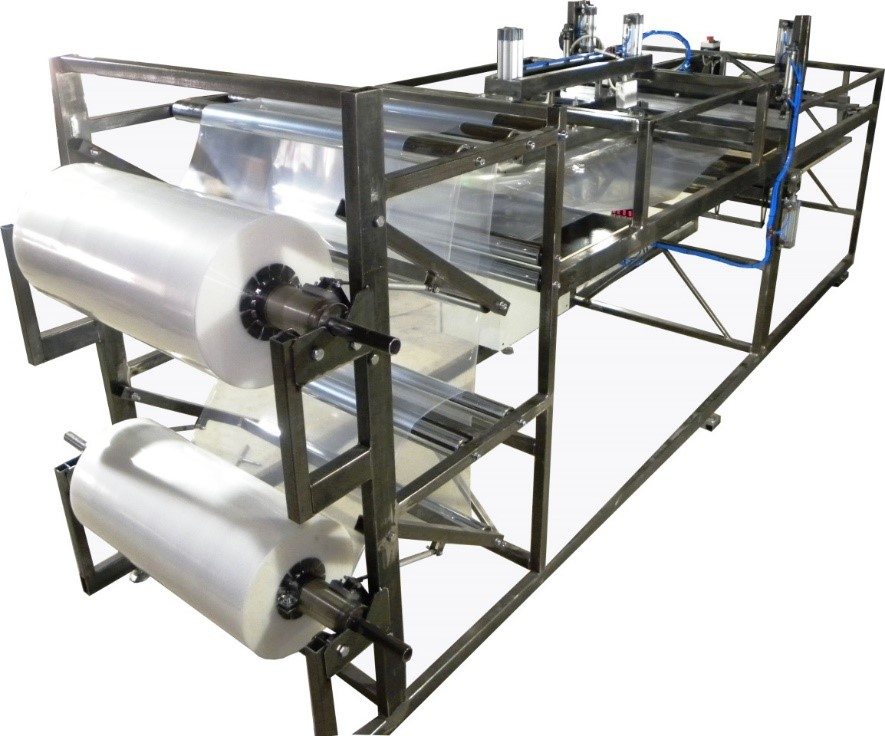

AUTOMATIC MACHINE FOR MANUFACTURING PACKAGES, MEASURES AND COVERS OF NOTEBOOKS WITH VARIOUS SIZES

12.500,00 EUR09.06.2022 | 570 |

PURPOSE:

The unit is designed for the production of bags by welding thermoplastic films from polymeric materials, as well as measured sheets of material and covers of notebooks. All three functions can be used on the same machine by changing the settings. It unwinds the web from a roll, welds a longitudinal seam, welds a transverse seam, cuts and stretches the web to a specified size in automatic (semi-automatic) mode. It is operated in rooms with temperature from + 20C to + 35C at relative air humidity up to 75%. Installation connection - to the alternating current network 220V and compressed air.

Link to analog video:

https://www.youtube.com/watch?v=sWVvLsUt-8s&feature=emb_logo

https://www.youtube.com/watch?v=4rCxrmoxvDo

https://www.youtube.com/watch?v=hYBPingHUNM

SPECIFICATIONS*:

*Any characteristics of the equipment can be changed, in accordance with the individual requirements of the customer.

• Material - vacuum, polypropylene film, canvas

• Film roll diameter - up to ø600 mm

• Roll width - according to customer requirements

• Package sizes - variable, up to 600x600 mm (according to customer requirements)

• Production - from 2 rolls of film, (1 -: - 2 streams)

• Performance o - up to 20 pcs/min (2 streams) o - up to 10 pcs / min (1 thread)

• Width of seams - 7-10 mm • Installation class - automatic

• Roll holders - 2 pieces

• Film advance - automatic

• Draw length - adjustable up to 600 mm (according to customer requirements)

• Type of sealers - "Euro"

• Tool heating - constant, adjustable up to 250ºС

• Sealers for longitudinal sealing - 1 piece, with the ability to move along the transverse axis

• Sealer transverse - 1 piece

• Multi-bladed cutting knife - 1 pc.

• Knife cutting - 1 piece (longitudinal)

• Burr that occurs when cutting off - removed with a vacuum cleaner (vacuum cleaner not included)

• Drive - pneumatic

• Mounting type - without foundation

• Control unit - electronic

• Setting strokes (cycles) multiple of 100.0 - on the control unit

• Operator - 1 person

• Connection - 220 v; 50 Hz; 3 kW; 6 atm

• Overall dimensions, (no more) - 2500 x 1000 x 1600 mm

• Weight (no more) - 400 kg.

DESIGN:

Installation design:

- the roll holder module has two roll installation units with a film sagging compensator, roll braking and guide shafts;

- a welder of a longitudinal seam with a knife for trimming the edge;

- cloth clamping in front of the transverse welder;

- a welder of a transverse seam with a cutting knife;

- module for extracting the product to a specified size;

- сontrol block.

The control unit provides:

- manual switching on and indication of power supply of the unit;

- button of emergency blocking of work;

- two independent thermostats for the temperature of welding tools, with manual switches and indicators;

- operating mode switch setting;

- refueling - automatic and indication of the selected operating mode;

- switch of automatic work cycles single - full - semi-package and indication of the selected cycle;

- start and stop buttons;

- a button for turning on the counter of products and an indicator for reaching the set number of products;

- buttons for activation of actuators in the setting mode;

- remote control with buttons for restarting the counter of products and emergency blocking of work.

Options and settings:

- working temperature of welders (on thermostats) - 0-2500С

- current counter (controller) - indication

- installation of the counter (controller) - 1-99 pieces

- welding time of the transverse seam (controller) - 0-20 sec

- when welding a longitudinal seam (controller) - 0-20 sec

- knife operation delay (controller) - 0-5 sec

- delay of actuation of hole punching (controller) - 0-3 sec

- hold release delay (controller) - 0-0.5 sec.

In the manufacture of equipment, components manufactured in Germany and Italy are used.

COST OF A MACHINE FOR MANUFACTURING PACKAGES, a warehouse in Kyiv: 12,500 euros

COST OF AN ADDITIONAL PULSE HEATING TOOL PACK AND CONTROL UNIT:2500 euros (if purchased together with the bag making machine)

The unit is designed for the production of bags by welding thermoplastic films from polymeric materials, as well as measured sheets of material and covers of notebooks. All three functions can be used on the same machine by changing the settings. It unwinds the web from a roll, welds a longitudinal seam, welds a transverse seam, cuts and stretches the web to a specified size in automatic (semi-automatic) mode. It is operated in rooms with temperature from + 20C to + 35C at relative air humidity up to 75%. Installation connection - to the alternating current network 220V and compressed air.

Link to analog video:

https://www.youtube.com/watch?v=sWVvLsUt-8s&feature=emb_logo

https://www.youtube.com/watch?v=4rCxrmoxvDo

https://www.youtube.com/watch?v=hYBPingHUNM

SPECIFICATIONS*:

*Any characteristics of the equipment can be changed, in accordance with the individual requirements of the customer.

• Material - vacuum, polypropylene film, canvas

• Film roll diameter - up to ø600 mm

• Roll width - according to customer requirements

• Package sizes - variable, up to 600x600 mm (according to customer requirements)

• Production - from 2 rolls of film, (1 -: - 2 streams)

• Performance o - up to 20 pcs/min (2 streams) o - up to 10 pcs / min (1 thread)

• Width of seams - 7-10 mm • Installation class - automatic

• Roll holders - 2 pieces

• Film advance - automatic

• Draw length - adjustable up to 600 mm (according to customer requirements)

• Type of sealers - "Euro"

• Tool heating - constant, adjustable up to 250ºС

• Sealers for longitudinal sealing - 1 piece, with the ability to move along the transverse axis

• Sealer transverse - 1 piece

• Multi-bladed cutting knife - 1 pc.

• Knife cutting - 1 piece (longitudinal)

• Burr that occurs when cutting off - removed with a vacuum cleaner (vacuum cleaner not included)

• Drive - pneumatic

• Mounting type - without foundation

• Control unit - electronic

• Setting strokes (cycles) multiple of 100.0 - on the control unit

• Operator - 1 person

• Connection - 220 v; 50 Hz; 3 kW; 6 atm

• Overall dimensions, (no more) - 2500 x 1000 x 1600 mm

• Weight (no more) - 400 kg.

DESIGN:

Installation design:

- the roll holder module has two roll installation units with a film sagging compensator, roll braking and guide shafts;

- a welder of a longitudinal seam with a knife for trimming the edge;

- cloth clamping in front of the transverse welder;

- a welder of a transverse seam with a cutting knife;

- module for extracting the product to a specified size;

- сontrol block.

The control unit provides:

- manual switching on and indication of power supply of the unit;

- button of emergency blocking of work;

- two independent thermostats for the temperature of welding tools, with manual switches and indicators;

- operating mode switch setting;

- refueling - automatic and indication of the selected operating mode;

- switch of automatic work cycles single - full - semi-package and indication of the selected cycle;

- start and stop buttons;

- a button for turning on the counter of products and an indicator for reaching the set number of products;

- buttons for activation of actuators in the setting mode;

- remote control with buttons for restarting the counter of products and emergency blocking of work.

Options and settings:

- working temperature of welders (on thermostats) - 0-2500С

- current counter (controller) - indication

- installation of the counter (controller) - 1-99 pieces

- welding time of the transverse seam (controller) - 0-20 sec

- when welding a longitudinal seam (controller) - 0-20 sec

- knife operation delay (controller) - 0-5 sec

- delay of actuation of hole punching (controller) - 0-3 sec

- hold release delay (controller) - 0-0.5 sec.

In the manufacture of equipment, components manufactured in Germany and Italy are used.

COST OF A MACHINE FOR MANUFACTURING PACKAGES, a warehouse in Kyiv: 12,500 euros

COST OF AN ADDITIONAL PULSE HEATING TOOL PACK AND CONTROL UNIT:2500 euros (if purchased together with the bag making machine)